BROADWAY EQUIPMENT: WHERE NEEDS MEET SOLUTIONS

This question is something that the innovation team at Broadway Equipment is constantly pondering when working with our current equipment. Due to our direct, ongoing interaction with the product in the field, we are able to quickly pull data and real-life scenarios from our customer-base, giving us an up-to-date flow of information that our chief engineers can pull from and help design better solutions and products for the future.

In creating new and improved design iterations, Broadway Equipment is also committed to keeping clients and customers alike well informed and updated on what’s new and what’s around the corner. Here is a quick peak and some of the latest improvements.

Conveyor System Improvements

Conveyor car washes are intricate and require many parts to work in synchronized tandem for the cleanest wash and dry. Fortunately, we have been building conveyor washes for decades, and even though we have the science down – there are always adaptations to be made to squeeze out every bit of efficiency and usability.

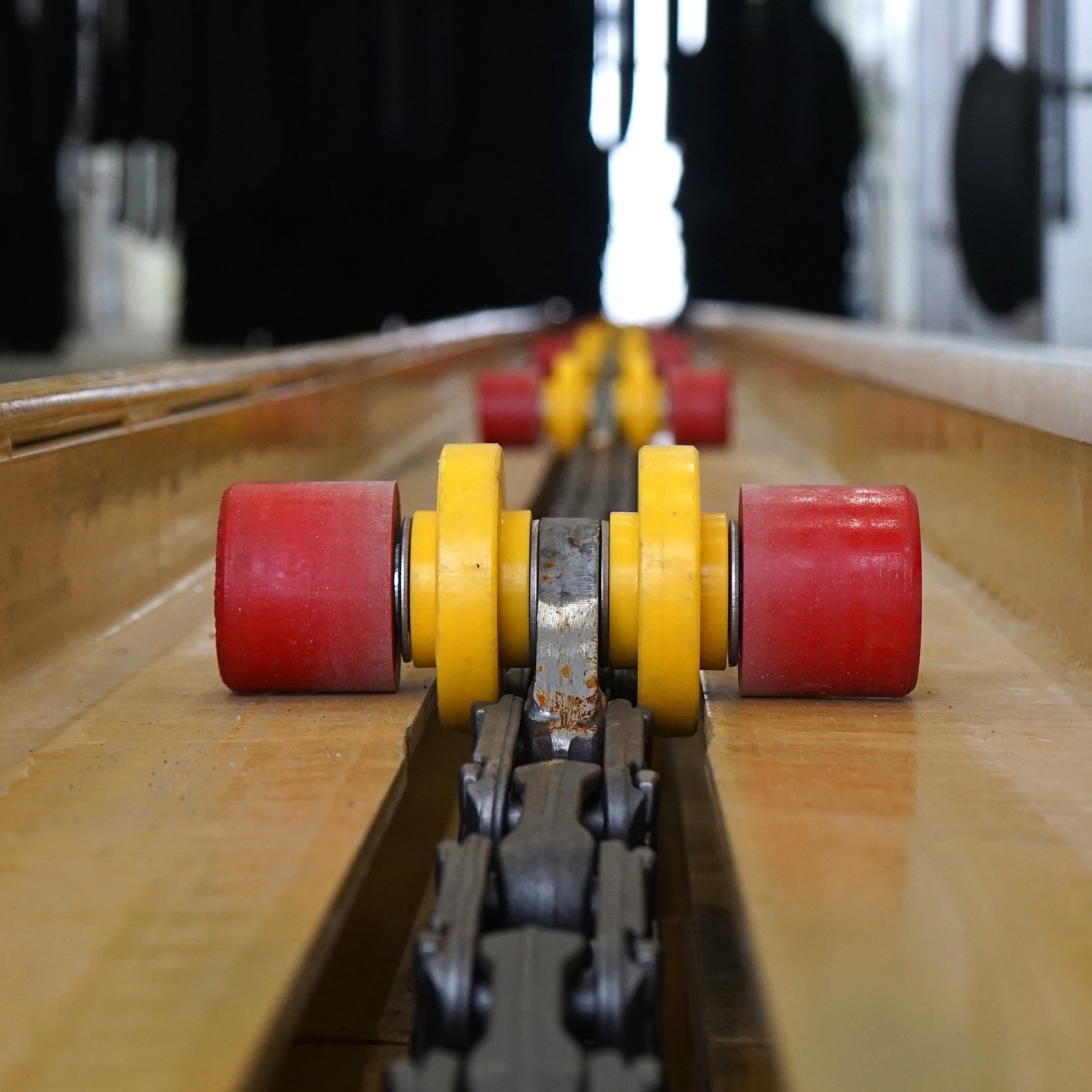

DUAL DRIVE SPROCKET SYSTEM

We have incorporated a sprocket drive unit on both ends of our newer conveyor systems, which will provide dual drive points for straighter travel, more controlled contact points, and less jamming points which help create a longer life structure for the entire system. This upgrade will contribute to less wear, lower maintenance requirements, and less opportunity for jams.

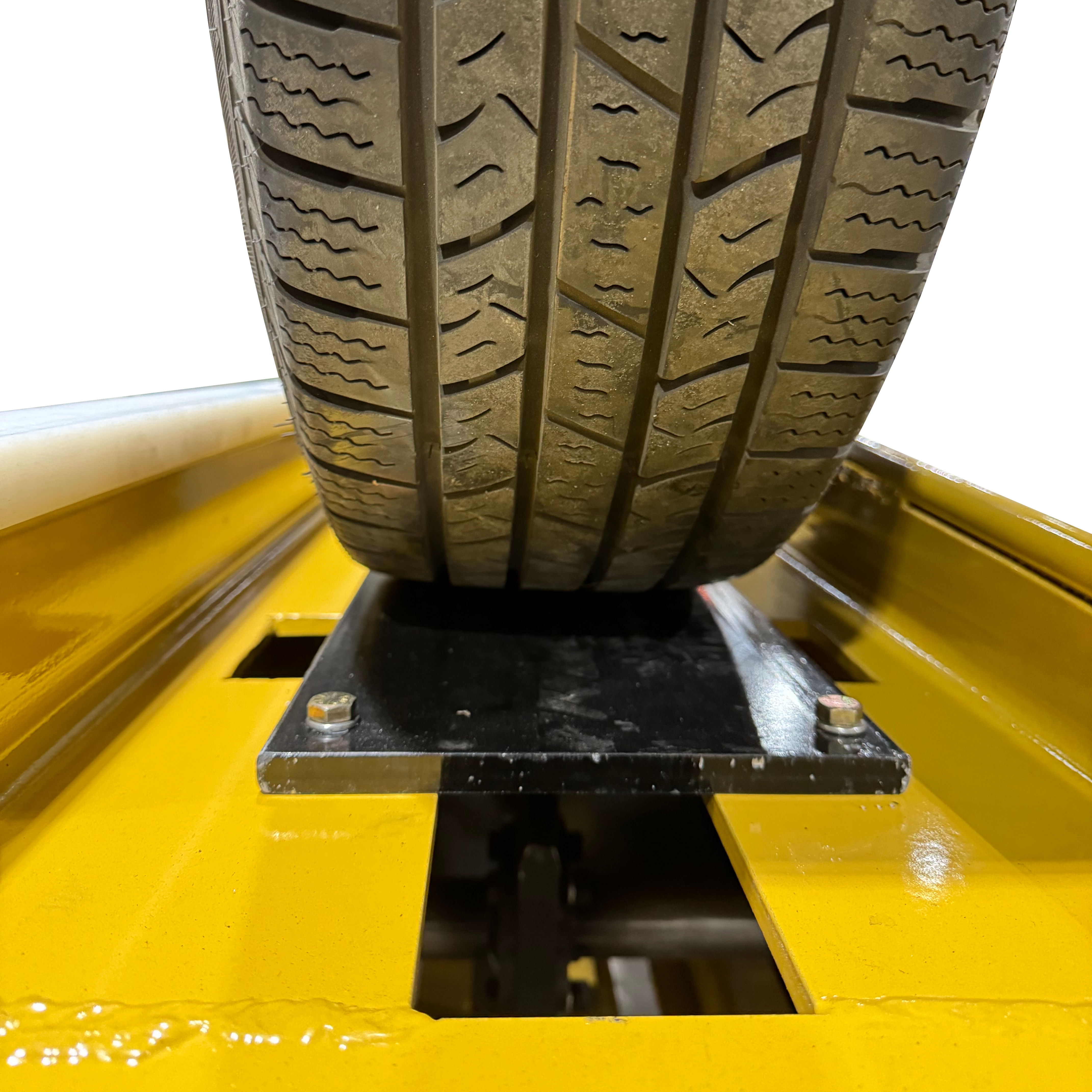

CONVEYOR WIDTH

Today’s automotive market has many unique and wide performance tires (not to mention heavy duty tires) that all can require a wider conveyor. Broadway has worked to redesign its conveyor to expand the capacity it can handle by over an inch in width. Our latest product can accommodate 14-inch-wide tires which will effectively handle nearly every car on the market.

LESS FRICTION, MORE DURABILITY

With the new triple track design, new dollies, and the use of more UHMW (ultra-high molecular weight polyethylene), there is more durability in the conveyor products. UHMW is an extremely durable plastic with high abrasion and wear resistance. It extends the life, lower the need for maintenance, and comes reduces repair costs.

Improvements to Other Equipment

Beyond our conveyors, Broadway is committed to offering customers a wide variety of car wash equipment and detailing solutions. These items also receive our constant drive to design improvements that lead the industry to the best solution. Some of those include:

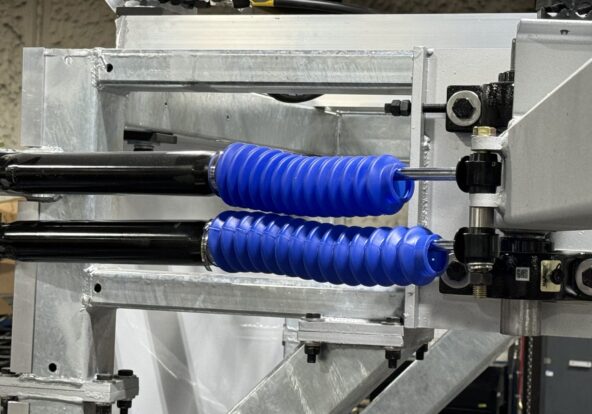

ADDITIONAL ARM CONTROL MECHANICS

We have added an additional control mechanism for the long arm on our drive thru wash which improves control. By adding additional control capability, the wash brush is more adjustable and will perform better on cleaning the front and back of vehicles.

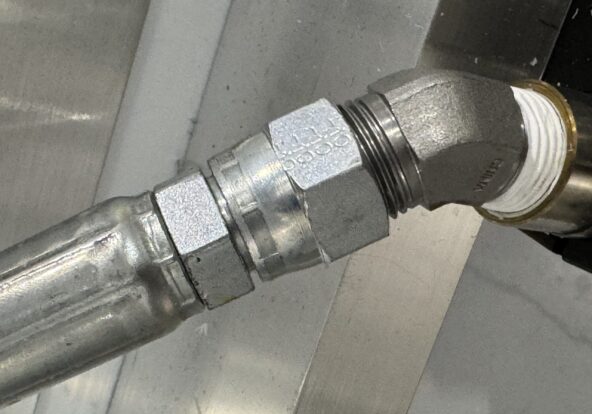

“TUFF SHIELD” COATING

The car wash environment is one that is susceptible to rust, which means we must continuously find new ways to control or eliminate it. A newly developed product we utilize is a “tuff shield” coating for metal fittings. This product is specifically designed to protect components of our equipment from the harsh environment and bring us one step closer to achieving 100% rust-free equipment.

WALK UP ALARM

This AI-integrated upgrade allows the onboard car wash screen to provide several walk up error messages to help solve problems easily and quickly to get the car wash operating. This information requires little or no interaction but it is easy to observe and can lead to instant repairs.

ODOR CONTROL THROUGH OZONEPRO

Water recycling is an important part of the future of the car wash industry. The recycling industry is seeing a lot of development to enhance results and further the commitment to re-using the wash water. Controlling the odor the water can produce is one of the main steps in making recycling water a better option.

Here at Broadway Equipment, our dedication to innovation is unwavering. Our commitment to research and development, combined with our responsiveness to customer feedback and market trends, ensures that we stay at the forefront of the industry. By continually refining our equipment, we not only meet the current needs of our clients but also anticipate future demands.

As we move forward, we will maintain our focus on enhancing efficiency, sustainability, and the overall user experience. Our goal is to provide car wash solutions that are not only effective and durable but also environmentally friendly and adaptable to the evolving automotive landscape. We look forward to sharing further innovations and improvements with our clients and the broader community, reinforcing our position as leaders in the car wash equipment industry.

Contact Our Team to Learn More or Share an Opportunity

Community is at the heart of all we do here at Broadway. If you’d like to learn more about us, we welcome you to reach out. If you know of an opportunity that Broadway could participate in, please let us know!